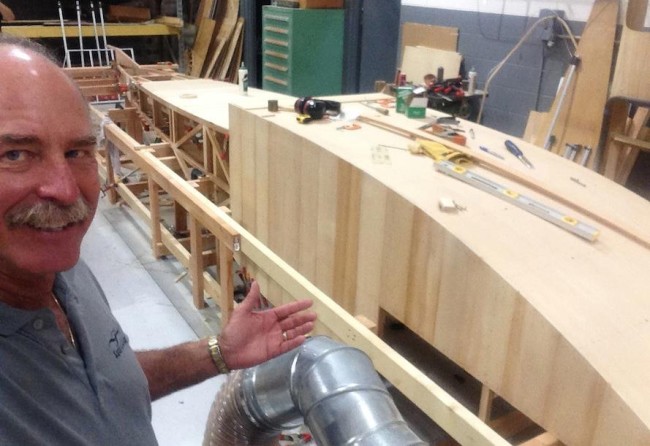

Our own Ken Kellett just got back from vacation and is beginning to plank the Benoist hull in earnest now as these updates from Kermit show:

The front step area gets three layers of 1/4″ x 4″ spruce and the sides and bottom aft of the step get 2 layers. Here’s a closer view of the step area:

Here’s a shot from the front:

The side strips begin vertical and the next layer goes forward and aft. The bottom begins forward and aft because it ultimately gets three layers. Originally, in the construction of old boats and early seaplanes, fabric would have been glued under the last layer of wood to help seal the hull. Because you won’t be able to see it, we will use fiberglass cloth and epoxy glue, which is stronger and should seal it better.

In addition to Ken, we have four others focusing on cables, turnbuckles, a cable tension tester, the fuel tank, and the drive system. The engine guy up north is making progress and will also do the radiator.

Five months and counting! Tick… tick… tick…